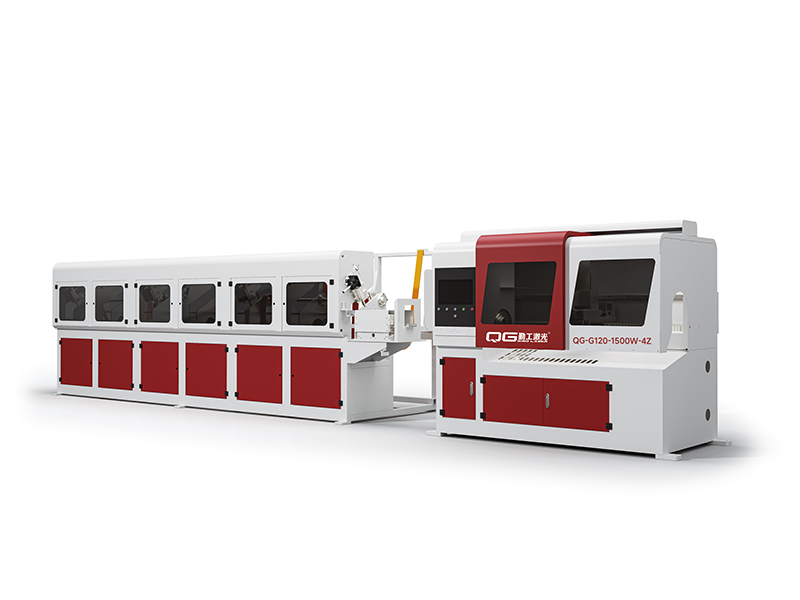

High-Speed Fully Automatic Three-dimensional Laser Pipe Cutting Machine

Technical parameters

|

| Project | Parameters |

| Laser power | 11500W( Optional 2000W/3000W) |

| Machine tool model | QG-G90-1500W-4Z/QG-G120-1500W-4Z |

| Processing range | Φ10~80mm/Φ10~110mm |

| X / Y axis positioning accuracy | ±0.1mm |

| X / Y axis repeated positioning accuracy | ±0.1mm |

| Working voltage | 380V/50HZ |

| Total Power | 12.6KW |

| Power protection level | IP54 |

A high-speed fully automatic three-dimensional laser pipe cutting machine is a machine tool that uses a laser beam to cut tubes and profiles of various materials. The laser beam is focused by a lens to a small spot, which melts or vaporizes the material at the point of focus. The machine can be programmed to cut complex shapes and patterns, and it can also cut tubes of different diameters and lengths.

The main advantages of high-speed fully automatic three-dimensional laser pipe cutting machines are:

· High speed: The laser beam can cut through material very quickly, making it a very efficient cutting method.

· High precision: The laser beam can be focused to a very small spot, resulting in high-precision cutting.

· Versatility: The machine can cut a wide variety of materials, including steel, aluminum, copper, and plastics.

· Automated operation: The machine can be programmed to cut complex shapes and patterns automatically, freeing up operators for other tasks.

Some of the specific features of high-speed fully automatic three-dimensional laser pipe cutting machines include:

· A powerful laser source, typically a fiber laser or a CO2 laser.

· A high-precision optical system to focus the laser beam.

· A robotic arm to move the laser beam around the workpiece.

· A CNC controller to control the movement of the laser beam and the robotic arm.

· A cutting head that can be rotated to cut tubes of different diameters.

· A fume extraction system to remove smoke and fumes from the cutting process.

High-speed fully automatic three-dimensional laser pipe cutting machines are used in a variety of industries, including:

· Manufacturing: The machines are used to cut tubes and profiles for a wide variety of products, such as car parts, furniture, and machine tools.

· Aerospace: The machines are used to cut tubes and profiles for aircraft and spacecraft.

· Medical: The machines are used to cut tubes and profiles for medical devices, such as stents and catheters.

· Construction: The machines are used to cut tubes and profiles for structural applications, such as bridges and buildings.

The cost of a high-speed fully automatic three-dimensional laser pipe cutting machine varies depending on the size and features of the machine. However, the machines typically cost several hundred thousand dollars.

If you are looking for a high-speed, precise, and versatile way to cut tubes and profiles, then a high-speed fully automatic three-dimensional laser pipe cutting machine is a good option. These machines can save you time and money, and they can produce high-quality cuts that meet your requirements.

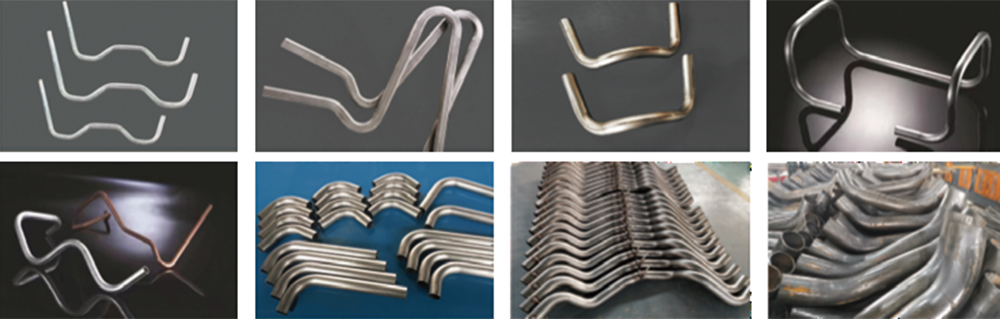

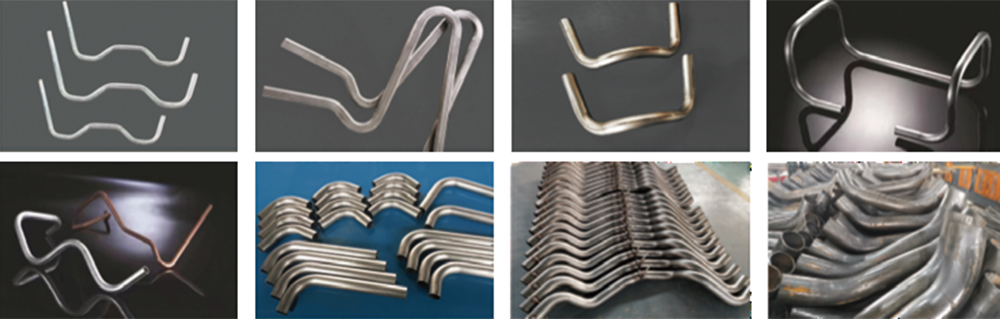

Processable pipe details

Service Support · QINGGONG Robot

Stricter quality control · Make quality better