With the continuous advancement of science and technology, welding technology has also ushered in an automated transformation. However, handheld welding machines still occupy an important position in the welding market. This article will lead you to have a deep understanding of this handheld welding machine and explore its market advantages.

1. Handheld welding machine: a pioneer in technological innovation

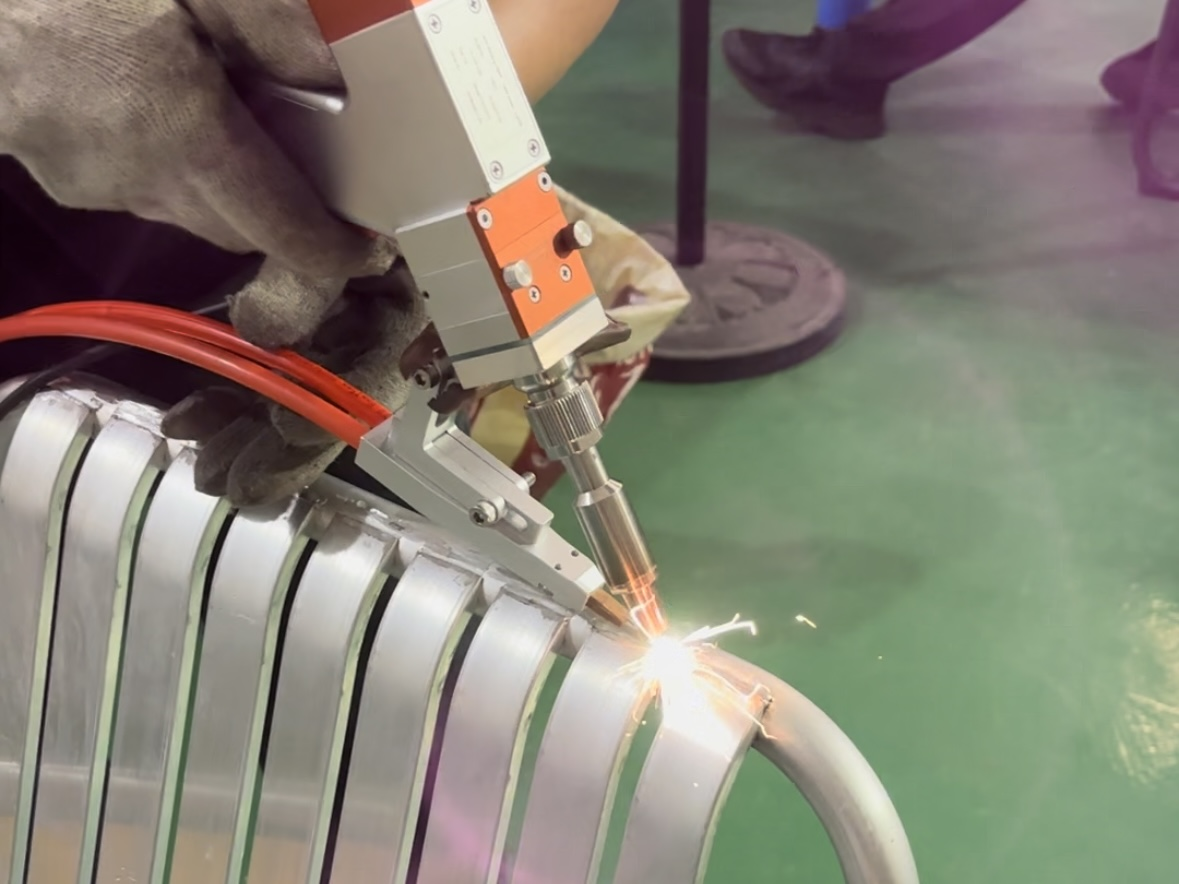

A handheld welding machine is a small, portable and easy-to-operate electric welding machine. It breaks through the constraints of traditional welding equipment and pushes welding technology to a new height. The working principle of the handheld welding machine is mainly based on arc welding. The welding current and voltage are set through the control panel, and the welding current is passed through the welding gun head to generate an arc to melt and weld two metal materials together. This design not only simplifies the welding process, but also greatly improves the welding efficiency and quality.

In recent years, handheld welding machines have made continuous breakthroughs in technology. Taking the latest self-cooling handheld laser welding machine as an example, it uses the industry's top direct cooling technology and intelligent control circulation constant temperature technology to achieve all-weather, self-cooling, and continuous light output functions. This innovation not only subverts the technical limitations of traditional water-cooled and air-cooled handheld laser welding machines, but also brings new ideas and solutions to the welding industry. With its excellent performance and stability, the self-cooling handheld laser welding machine has been widely used in metal plates, chassis, water tanks, distribution boxes and other cabinets, cabinets, kitchen utensils, stainless steel door and window guardrails and other fields.

2. Market advantages: efficient, convenient and intelligent

Handheld welding machines have shown strong competitiveness in the market, mainly due to their high efficiency, convenience and intelligence.

First of all, handheld welding machines have extremely high welding efficiency. Laser welding, with its advantages of good beam quality, fast welding speed, firm and beautiful welds, brings users efficient and perfect welding solutions. Compared with traditional welding methods, handheld laser welding machines can significantly improve the yield rate and reduce production costs. At the same time, the characteristics of high electro-optical conversion efficiency and low energy consumption also make handheld welding machines outstanding in energy saving and environmental protection.

Secondly, handheld welding machines are portable and flexible, and have a wide range of applications. Its light weight and small size design allow users to perform welding operations anytime and anywhere, especially suitable for small-scale repairs, home repairs, handicraft production and other occasions. In addition, the handheld welding machine is also highly safe. The welding nozzle is only effective when it touches the metal, and the touch switch has a body temperature sensing function, which further ensures the safety of the user.

Finally, the handheld welding machine is highly intelligent. Modern handheld welding machines are often equipped with advanced control systems and intelligent temperature control systems, which can achieve precise temperature control and automatic sensing of welding status. This not only improves the welding quality, but also reduces the difficulty of operation, allowing ordinary workers to start work after a short training. This intelligent trend not only improves work efficiency, but also promotes the transformation and upgrading of the welding industry.

3. Application scenarios: extensive and diverse

Handheld welding machines have been widely used in many industries due to their high efficiency, convenience and intelligence.

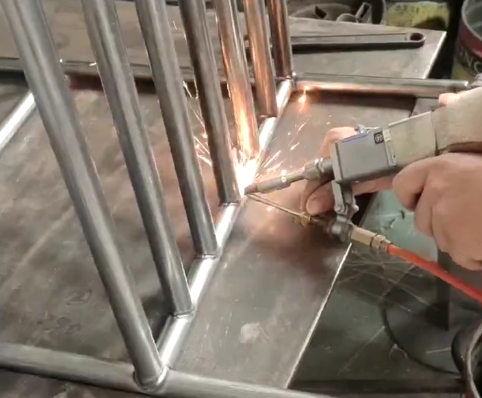

In traditional manufacturing industries such as the bathroom industry, the eyewear industry, and the hardware industry, handheld welding machines are widely used in complex and irregular welding processes such as stainless steel sinks, tap water pipes, stainless steel round pipe tees, and floor drains. Its flexible welding methods and high-quality welds make these products more beautiful and durable.

In high-tech fields such as the automotive industry and the electronics industry, handheld welding machines also play an important role. For example, in the process of automobile manufacturing, handheld welding machines can accurately weld automobile door panels, bumpers and other parts; in the process of electronic product manufacturing, handheld welding machines can be used for welding precision parts such as circuit boards and battery panels.

In addition, handheld welding machines are also suitable for many industries such as home furnishings, kitchen utensils, and medical equipment. Its diverse application scenarios and wide applicability make handheld welding machines a star product in the welding industry.

In summary, as the new darling of the welding industry, handheld welding machines have won wide recognition in the market for their high efficiency, convenience, and intelligence. With the continuous advancement of technology and the continuous expansion of application scenarios, handheld welding machines will continue to lead the new development trend of the welding industry in the future.