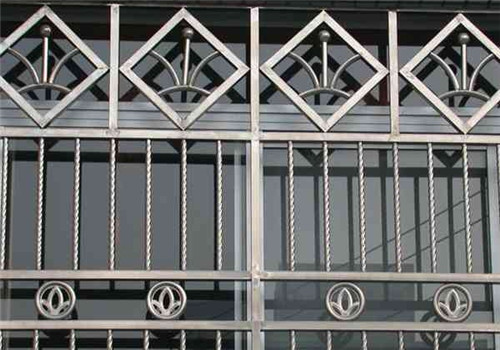

In the field of modern building safety and protection, anti-theft nets are widely used in various places such as residences, shops, schools, hospitals, etc.Laser pipe cutting machines, pipe bending machines and laser welding machines play a vital role in the production process of anti-theft nets. This article will explore the connection between the three in detail and expand through three subheadings.

1. Laser pipe cutting machine: a precise cutting tool in the production of anti-theft nets

Laser pipe cutting machine is one of the key equipment in the production process of anti-theft nets. It uses a high-energy-density laser beam to accurately cut steel pipes.

1.1 Working principle of laser pipe cutting machine

The working principle of laser pipe cutting machine is to focus the laser beam on the surface of the steel pipe, and melt and gasify the steel pipe instantly through the high-energy-density laser beam, so as to achieve the purpose of cutting. Laser cutting has the advantages of non-contact, fast speed, high precision, and good edge quality. It is very suitable for cutting needs of mass production such as anti-theft nets.

1.2 Application of laser pipe cutting machine in anti-theft net production

In the process of anti-theft net production, laser pipe cutting machine is mainly used to accurately cut steel pipes. First, according to the design requirements, use CAD software to draw the drawings of the anti-theft net and generate the cutting path. Then, put the steel pipe into the silo of the laser pipe cutting machine and send it to the cutting area through the automatic feeding system. The laser pipe cutting machine will accurately cut the steel pipe according to the preset cutting path. After the cutting is completed, the cut steel pipe is transported to the next process through the automatic discharge system.

The application of laser pipe cutting machine in the production of anti-theft nets not only improves the cutting accuracy and efficiency, but also reduces the labor intensity of workers.

2. Pipe bending machine: shaping the colorful forms of anti-theft nets

Pipe bending machine is another important equipment in the production process of anti-theft nets. It is mainly used to bend steel pipes into the required shape. In the production of anti-theft nets, it is sometimes necessary to make anti-theft nets with complex shapes such as arcs and waves, which requires the use of pipe bending machines for bending.

2.1 Working principle of pipe bending machine

The working principle of pipe bending machine is to bend steel pipes through molds and pressure wheels. During the bending process, the steel pipe will be placed in the mold and bent into the desired shape through the extrusion of the pressure wheel. The mold and pressure wheel of the pipe bending machine can be replaced and adjusted according to different bending requirements to meet the production needs of anti-theft nets of different shapes and sizes.

2.2 Application of pipe bending machine in the production of anti-theft nets

In the production process of anti-theft nets, pipe bending machines are mainly used to bend steel pipes into the desired shape. The application of pipe bending machine in the production of anti-theft nets not only enriches the shape and style of anti-theft nets, but also improves their structural stability and bearing capacity. At the same time, the pipe bending machine has the advantages of easy operation and high production efficiency, providing strong support for anti-theft net production companies.

3. Laser welding machine: realizing efficient welding of anti-theft nets

Laser welding machine is another key equipment in the production process of anti-theft nets. It uses laser beams to melt and solidify metals to achieve the purpose of welding. In the production of anti-theft nets, laser welding machines have become the preferred equipment for welding anti-theft nets with their high efficiency and precise welding characteristics.

3.1 Working principle of laser welding machine

The working principle of laser welding machine is to focus the laser beam on the weld and melt and solidify the metal through the energy of the laser beam. Laser welding has the advantages of high weld forming accuracy, fast welding speed and no pollution, which is very suitable for the welding needs of anti-theft nets.

3.2 Application of laser welding machine in the production of anti-theft nets

In the production process of anti-theft nets, laser welding machines are mainly used to connect various components together. First, according to the design requirements, the cut steel pipes and bent pipes are assembled to form the frame of the anti-theft net. Then, the welds are welded using a laser welding machine. During the welding process, the welding parameters and welding speed need to be strictly controlled to ensure the quality and strength of the welds. After welding, the welds need to be polished and trimmed to improve their surface quality and aesthetics.

The application of laser welding machines in the production of anti-theft nets not only improves the welding quality and efficiency, but also reduces the energy consumption and pollution during the welding process.

4. Conclusion

In summary, laser pipe cutting machine, pipe bending machine and laser welding machine play a vital role in the production process of anti-theft nets.