With the rapid development of science and technology, the construction machinery industry is undergoing unprecedented changes. Traditional equipment such as excavators and loaders are closely combined with modern high-tech equipment such as laser cutting machines, pipe bending machines and laser welding machines, jointly promoting the progress and development of the industry. This article will explore how laser technology and traditional machinery can be deeply integrated from three aspects: the combined application of construction machinery and laser cutting machines, the role of pipe bending machines in construction machinery, and the innovative application of laser welding machines in construction machinery manufacturing, and help the construction machinery industry move towards the path of innovative development.

1. Laser cutting machine: the precision "scalpel" for construction machinery manufacturing

In the construction machinery industry, laser cutting machines are widely used in the cutting and processing of various metal materials. Structural parts of equipment such as excavators and loaders, such as frames, booms, and dippers, are usually welded from thick steel plates. These structural parts have complex shapes and high dimensional accuracy requirements. Traditional manual cutting or mechanical cutting methods are difficult to meet production needs. Laser cutting machines can easily cope with these challenges and achieve high-precision and high-efficiency cutting processing.

In addition, another important application of laser cutting machines in the construction machinery industry is plate cutting. Bulldozers have hoods, floor wings and other parts, which are usually made of thin steel plates or stainless steel plates. These parts have various shapes, high dimensional accuracy requirements, and need to be mass-produced. The laser cutting machine can complete the cutting and processing of multiple parts at one time, which not only improves production efficiency but also ensures product quality.

The application of laser cutting machines has not only significantly improved the production efficiency and product quality of the construction machinery industry, but also promoted the transformation and upgrading of the industry. Therefore, laser cutting machines not only help to enhance the brand image and market competitiveness of construction machinery companies, but also can promote the development of the entire industry to a higher level.

2. Pipe bending machine: the "shaper" of the vascular system of construction machinery

In the construction machinery industry, pipe bending machines are mainly used to manufacture various pipeline systems, such as hydraulic pipelines, fuel pipelines, cooling pipelines, etc. These pipeline systems connect various parts of construction machinery and play the role of transmitting liquids, gases and other media. Pipe bending machines can bend these pipes into various complex shapes to meet the design requirements of construction machinery.

For example, in equipment such as excavators and loaders, hydraulic pipes are important channels for connecting hydraulic pumps, hydraulic cylinders and other components. These pipes need to be bent into various shapes to adapt to the structural layout of the equipment. The pipe bending machine can accurately bend these pipes into the required shapes according to the design requirements to ensure the normal operation of the hydraulic system.

In addition, the pipe bending machine can also be used to manufacture other pipeline systems in engineering machinery, such as fuel pipes, cooling pipes, etc. These pipes also need to be bent into various shapes to meet the working needs of the equipment. The application of the pipe bending machine makes the manufacture of these pipes more convenient and efficient, providing a strong guarantee for the reliable operation of engineering machinery.

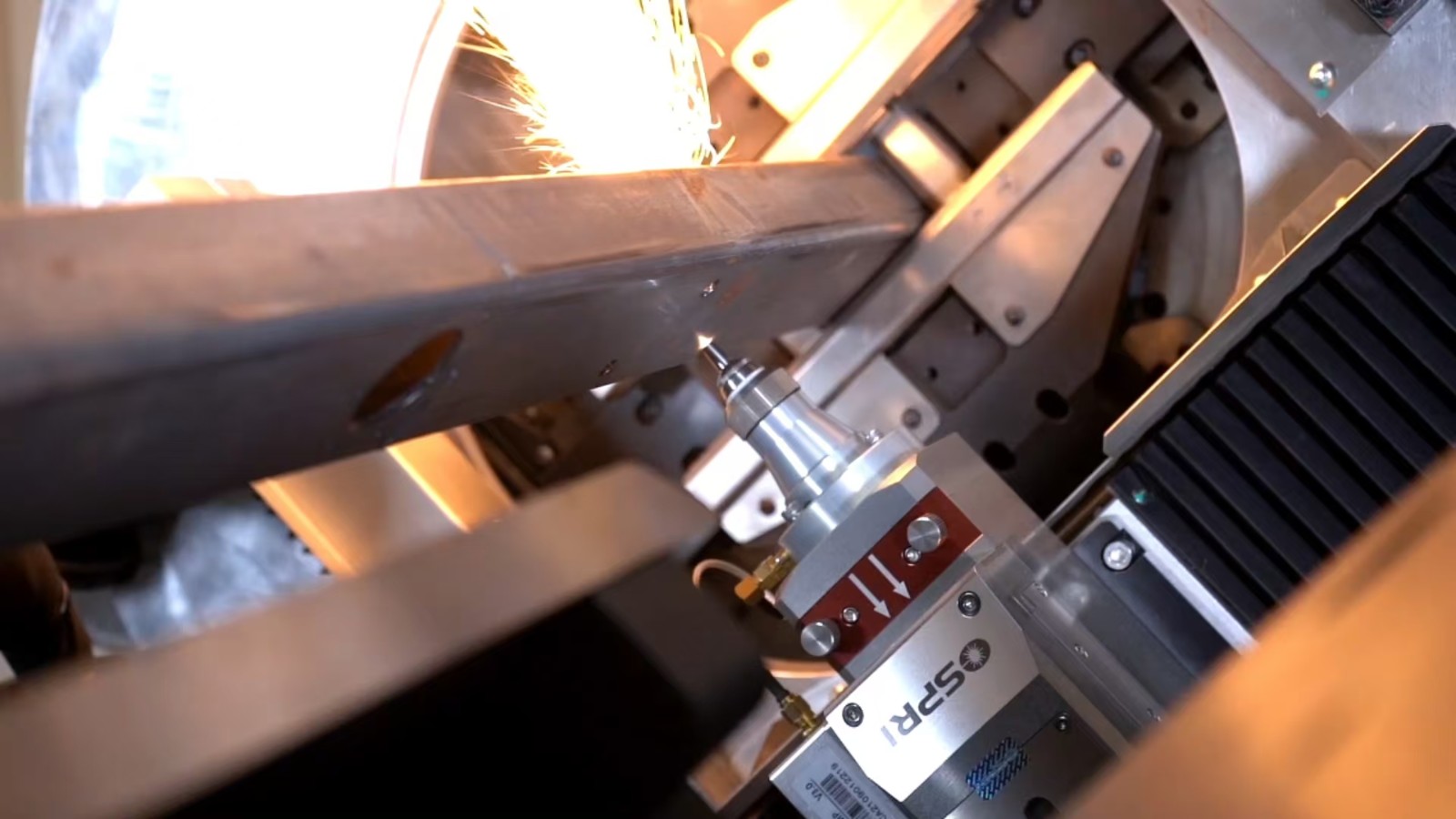

3. Laser welding machine: "seamless connector" for engineering machinery manufacturing

In engineering machinery manufacturing, laser welding machines are widely used in the welding of various structural parts. The frames, booms, buckets and other structural parts of equipment such as excavators and loaders are usually welded from thick steel plates. With its high-precision and high-efficiency welding characteristics, the laser welding machine can meet the welding needs of these structural parts and ensure the stable and reliable quality of the welds.

In addition, the laser welding machine can also be used for the welding of other parts in engineering machinery. For example, welding of engine blocks, cylinder heads and other components, as well as sealing welding of hydraulic cylinders, fuel tanks and other components. The application of laser welding machines makes the welding of these components more reliable and stable, providing a strong guarantee for the reliable operation of construction machinery.

Summary

To sum up, modern high-tech equipment such as laser cutting machines, pipe bending machines and laser welding machines play an important role in the construction machinery industry. Their application not only improves the production efficiency and product quality of construction machinery products, but also promotes the transformation, upgrading and sustainable development of the industry.