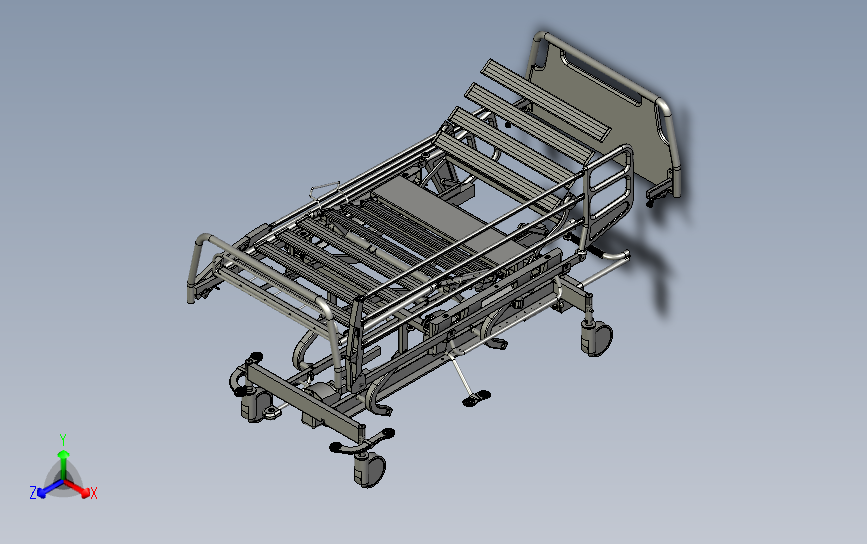

In the process of processing the metal part of the medical bed, the application of modern processing equipment such as laser plate cutting machine, laser tube cutting machine, tube bending machine and laser welding machine not only improves production efficiency, but also ensures the accuracy and quality of the product. This article will combine these equipment to elaborate on the processing process of the metal part of the medical bed.

1. Laser cutting: the perfect combination of high efficiency and precision

The metal parts of the medical bed, such as the bed frame, beams, longitudinal beams, etc., need to be precisely cut. The traditional cutting method is not only inefficient, but also difficult to ensure accuracy. The introduction of laser cutting technology solves this problem.

Application of laser cutting machine

The laser cutting machine uses a laser beam to move quickly on the surface of the metal sheet to achieve high-precision and high-efficiency cutting. The cutting method using the laser cutting machine has the advantages of smooth cut, high precision, fast speed and high material utilization. In the processing of the medical bed, the laser cutting machine can complete the cutting of the bed frame main board, side panels, beams and other plates. After these plates are cut by the laser plate cutting machine, they can be directly used for subsequent assembly work without secondary processing, which greatly improves production efficiency.

Application of laser pipe cutting machine

In addition to plates, various metal pipes are also needed for the processing of medical beds, such as the support pipes of bed legs and the crossbars of guardrails. The cutting of these pipes also requires high precision and high efficiency. The laser pipe cutting machine perfectly meets this demand. The laser pipe cutting machine uses a laser beam to perform three-dimensional cutting of pipes, which can achieve cutting at any angle and in any shape. During the processing of medical beds, the laser pipe cutting machine can complete the cutting of pipes such as bed leg support pipes and guardrail crossbars. After these pipes are cut by the laser tube cutting machine, they are not only high in precision, but also smooth incisions, and can be directly used for assembly without subsequent processing.

2. Pipe bending technology: shaping the perfect lines of medical beds

The design of medical beds often needs to consider the comfort and convenience of patients, so the lines of the bed frame are often smoother. This requires the use of pipe bending technology to bend metal pipes into the required shape.

The pipe bending machine is the main equipment for bending metal pipes. In the processing of medical beds, it is necessary to select a pipe bender that can accurately control the bending angle and radius. This type of pipe bending machine usually uses a CNC system, which can preset bending parameters to achieve precise bending. At the same time, the pipe bendping machine also has functions such as automatic feeding and automatic positioning, which greatly improves production efficiency.

In the processing of medical beds, pipe bending machine is mainly used for bending pipes such as bed leg support pipes and guardrail crossbars. After being processed by the pipe bending machine, these pipes can present the required lines and shapes, adding beauty to the overall design of the medical bed.

3. Laser welding: ensuring the stability and safety of medical beds

As medical equipment, the stability and safety of medical beds are crucial. The connection between metal parts requires a reliable welding method. Laser welding technology, with its advantages of high strength, high precision and no pollution, has become the first choice for welding metal parts of medical beds.

Principle and characteristics of laser welding machine

The laser welding machine uses a high-energy-density laser beam as a heat source to heat the surface of the workpiece through laser radiation, so that the workpiece melts and forms a weld. This welding method has the advantages of narrow weld, high strength, small heat-affected zone and small deformation. At the same time, no smoke and splash are generated during laser welding, which is pollution-free to the environment and meets the clean production requirements of medical equipment.

Application of laser welding machine in medical bed processing

During the processing of medical beds, laser welding machines are mainly used for the connection between plates such as bed frame mainboards, side plates, and crossbeams, as well as the welding between pipes such as bed leg support tubes and guardrail crossbars. After these parts are welded by laser welding machines, the welds are smooth and strong, which can ensure the stability and safety of medical beds. At the same time, laser welding machines can also reduce material waste and processing time and improve production efficiency.

4. Summary and Outlook

Modern processing equipment such as laser cutting machines, laser pipe cutting machines, pipe bending machines and laser welding machines play an important role in the processing of the metal parts of medical beds. They not only improve production efficiency, but also ensure the accuracy and quality of products. With the continuous advancement of science and technology and the continuous updating of medical equipment, the processing of medical beds in the future will pay more attention to intelligence, automation and greening. Therefore, we need to continuously explore and apply new processing technologies and equipment to promote the sustainable development of the medical bed processing industry.