With the general improvement of the quality of life, more and more people have begun to have the need for fitness. In order to ensure the quality and safety of the equipment, modern fitness equipment manufacturers usually rely on advanced processing technology and equipment, such as laser cutting machines, pipe bending machines and laser welding machines. This article will introduce in detail the main processes of fitness equipment processing and the key role of these equipment in it.

1. Material cutting: application of laser cutting machine

In the manufacturing process of fitness equipment, the cutting of metal materials is an important step. These materials need to be accurately cut and formed according to the design drawings. Laser cutting machines play a key role in this link.

The laser cutting machine cuts metal sheets through a high-energy laser beam. Its advantages are high precision, high speed and flexible cutting path. Compared with traditional mechanical cutting methods, laser cutting machines can effectively reduce cutting errors and material waste. This not only improves processing efficiency, but also ensures the quality of the equipment. Especially in the processing of complex parts, laser cutting machines can achieve automated production through computer control, greatly improving production flexibility.

2. Tube forming: high-precision operation of pipe bending machines

Many parts of fitness equipment are made of metal pipes, such as barbell racks, elliptical machine brackets and exercise bike frames. These metal pipes need to be bent and formed to meet design requirements and ensure the strength and stability of the product. Pipe bending machines are key equipment used to perform this step.

Modern pipe bending machines use numerical control (CNC) technology to accurately control the bending angle and strength to ensure that each bending point meets the design standards. Pipe bending machines can handle pipes of different diameters and thicknesses, which makes them widely used in the manufacture of fitness equipment. For example, the frame of the dumbbell rack and the bracket of the strength training equipment require precision pipe bending to meet the requirements of high strength and high load-bearing capacity. In addition, the automation characteristics of CNC pipe bending machines greatly improve production efficiency, while also reducing errors and safety risks caused by manual operation.

The use of pipe bending machines not only makes the design of fitness equipment more diverse, but also ensures the efficient use of materials during the manufacturing process.

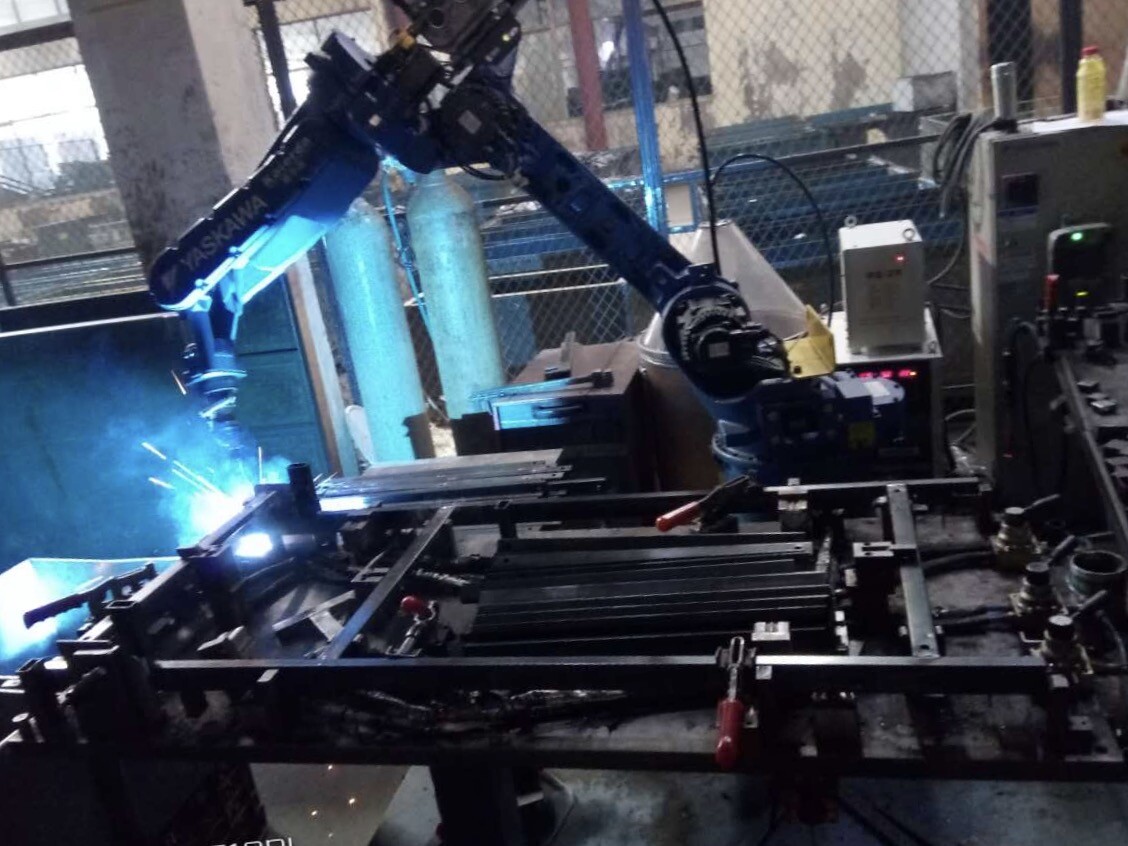

3. Assembly and welding: Precision connection of laser welding machine

The final assembly and connection of fitness equipment is the last important link in the manufacturing process. In this stage, the laser welding machine plays a vital role. Traditional welding methods often produce a large heat-affected zone, which is easy to cause deformation or damage of the material, while the laser welding machine quickly melts the metal surface through a high-energy laser beam to achieve a high-strength, low-deformation connection.

The laser welding machine has the ability to accurately control welding parameters, such as laser power, welding speed, and focal position. The precise adjustment of these parameters can ensure the quality of each weld point and avoid the problems of uneven welds and insufficient strength in traditional welding. The use of laser welding machines not only improves the welding quality, but also shortens the production time, making the entire manufacturing process more efficient.

For example, when manufacturing strength training equipment, a large number of welding connections are required between the frame and the supporting parts,the application of laser welding technology ensures the high strength and high reliability of these connection points.

4. Surface treatment and testing: ensuring the durability and safety of equipment

After completing the main processing and welding, fitness equipment usually needs surface treatment to improve its durability and aesthetics.At the same time, manufacturers will conduct strict quality inspections on fitness equipment. Using advanced testing equipment and technology, the strength, stability and welding quality of each finished product are tested to ensure that it meets industry standards.

5. Summary: Advanced processing technology empowers fitness equipment manufacturing

From material cutting to final assembly welding, every step is inseparable from the support of modern high-tech equipment, such as laser cutting machines, pipe bending machines and laser welding machines. For manufacturers, the continuous introduction and improvement of these advanced equipment is the key to maintaining market competitiveness and improving product quality.